The logistics industry is evolving faster than ever before. Increasing consumer demands, global disruptions, and complex supply chains are driving companies to seek smarter, more responsive technologies. Among these, Artificial Intelligence (AI) is revolutionising how goods move from origin to destination.

AI in logistics is no longer a futuristic concept; it’s now a critical driver of efficiency, transparency, and cost reduction. This comprehensive guide explores the components, applications, and real-world impact of AI in logistics.

Defining “AI in Logistics”

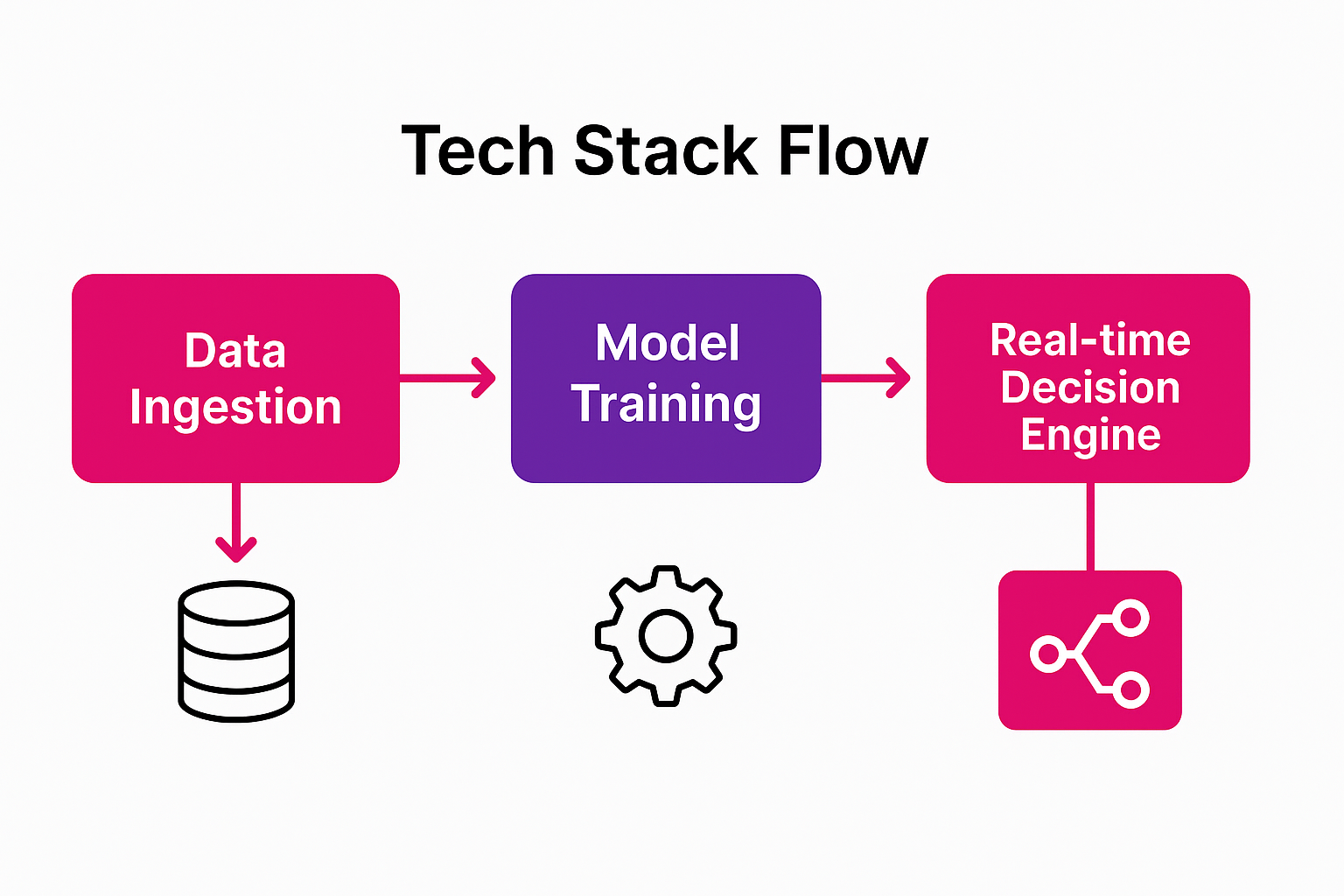

AI in logistics refers to the integration of machine learning, predictive analytics, computer vision, and natural language processing into supply chain and transportation operations. These technologies enable intelligent decision-making, process automation, and continuous optimisation.

Why Businesses Need AI in Logistics

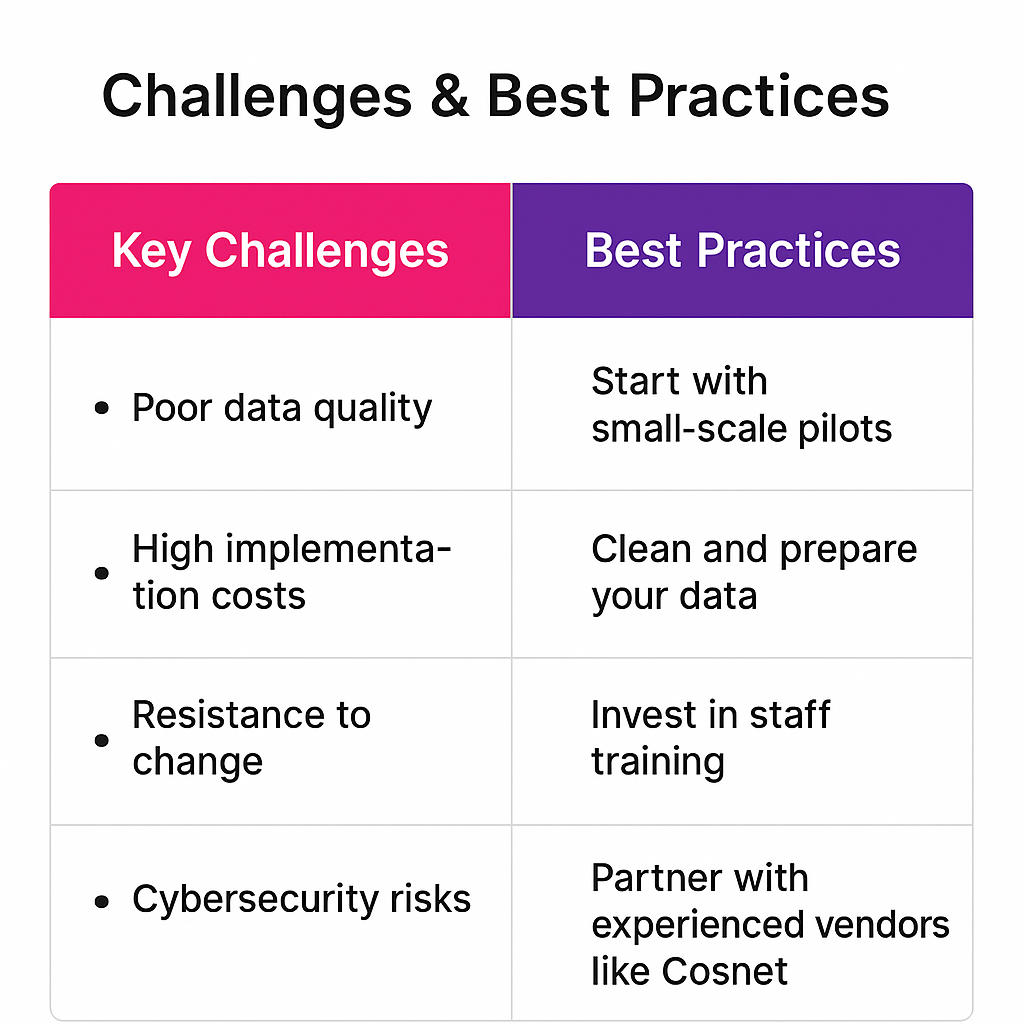

Modern logistics face numerous challenges:

- Volatile demand patterns

- Tight delivery schedules

- Rising operational costs

- Data overload

AI addresses these issues by offering:

- Real-time decision-making

- Enhanced forecasting

- Dynamic resource allocation

- Smarter customer service

According to Precedence Research, the AI in logistics market is expected to surpass USD 50 billion by 2032, growing at a CAGR of over 21%.

Core AI Technologies

| Technology | Application | Impact |

|---|---|---|

| Machine Learning | Demand Forecasting | Reduced overstock and stockouts |

| Computer Vision | Inventory Scanning | Faster and accurate tracking |

| NLP | Chatbots & Voice Assistants | 24/7 Customer Support |

| Predictive Analytics | Maintenance Scheduling | Lower downtime and costs |

| Reinforcement Learning | Route Optimization | Increased delivery speed |

Real-World Use Cases

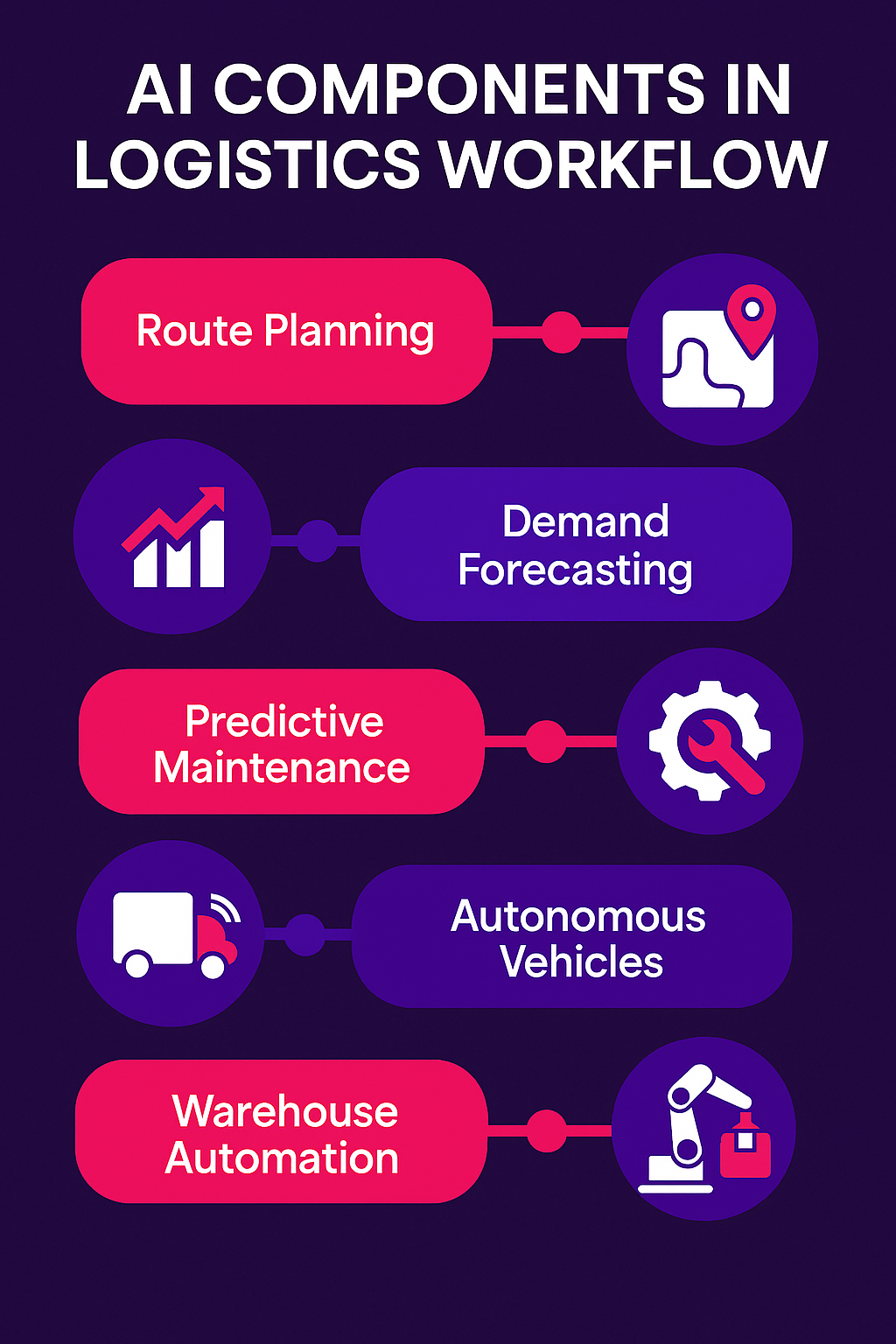

Route Optimization

UPS uses AI to save millions of gallons of fuel yearly through optimised delivery routes. Algorithms adjust in real-time to traffic and weather.

Warehouse Automation

Amazon uses AI-powered robots to automate sorting, packing, and inventory checks, improving warehouse productivity.

Demand Forecasting

Walmart applies machine learning to predict inventory needs during peak seasons, enhancing shelf availability.

Predictive Maintenance

UPS applies AI to monitor truck parts and pre-empt failures, reducing breakdowns by up to 26%.

Customer Support Chatbots

FedEx uses AI chatbots to resolve tracking issues and delivery rescheduling, handling thousands of queries daily.

Business Benefits

- Cost Efficiency: Reduce labour and fuel costs through automation.

- Speed & Accuracy: Faster delivery and fewer errors.

- Scalability: AI scales operations without increasing headcount.

- Customer Satisfaction: Better ETAs and support services.

- Sustainability: Optimised routes reduce emissions.

Future Trends

- Autonomous Vehicles: AI-driven trucks and drones for delivery

- Digital Twins: Virtual logistics models for scenario simulation

- Sustainable AI: Optimising energy and emissions

- Hyperpersonalisation: Custom delivery options using behaviour data

- Blockchain + AI: Enhancing security and traceability

How to Get Started

- Audit your current logistics operations

- Identify pain points and inefficiencies

- Select a manageable pilot use case

- Choose a reliable tech partner

- Launch, track KPIs, and iterate

Tools & Vendors

| Tool | Purpose | Ideal For |

| Google AI Platform | ML Model Deployment | Enterprises |

| AWS SageMaker | Training/Deployment | Developers |

| Azure ML Studio | GUI-based ML | SMEs |

| Cosnet AI Suite | Custom Logistics AI | Scalable Solutions |

Conclusion & Next Steps

AI in logistics is not just a trend—it’s a necessity for companies that want to stay competitive. By embracing automation, intelligence, and predictive analytics, logistics providers can drastically improve their performance.

Next Step: If you’re ready to explore how AI can transform your logistics operations, reach out to Cosnet for a consultation tailored to your goals.

FAQs

Q1: Is AI expensive for small logistics firms?

While enterprise-scale AI systems can be costly, many logistics companies start with budget-friendly solutions like AI-powered chatbots or route optimisation tools. These small wins deliver measurable ROI and justify further investment.

Q2: Will AI replace human workers in logistics?

AI is designed to augment human capabilities, not replace them. It automates repetitive tasks, enabling workers to focus on higher-value responsibilities such as strategic planning, relationship management, and exception handling.

Q3: How long does it take to implement AI in logistics?

Implementation timelines vary based on project scope. A chatbot or analytics dashboard can take 4–8 weeks, while an integrated warehouse automation system may take 6–12 months. Pilots typically help validate value before full deployment.

Q4: Is AI secure for handling sensitive logistics data?

Yes, when implemented correctly. Leading platforms offer encryption, access controls, and compliance with global standards like GDPR. It’s crucial to partner with experienced vendors who prioritise cybersecurity.

Q5: What kind of data is needed to run AI in logistics?

Historical shipment records, GPS logs, traffic data, weather conditions, customer queries, and inventory levels. Clean, labelled, and well-structured data improves AI model performance and business outcomes.